|

|

|

|

○

Overview

○

Synchronous Power-train

●

Windflow™ 500

Executive Flyer

Power-train Brochure

|

The Windflow™

500 |

|

Proven mid-size turbine design for a wide

range of applications. Our wind turbines are cost-effective, because they

have a world-leading ratio of energy output to turbine weight, and they

eliminate the need for power electronics.

|

|

|

|

SyncWind. will work with established or start-up wind

turbine manufacturers who are interested to build the Windflow™ 500 turbine.

Please see the photo gallery and the details below. |

Monan in the Outer Hebrides, Scotland

Gebbies Pass, New Zealand

Monan in the Outer Hebrides, Scotland

Easter Aberchalder in the highlands above Loch Ness, Scotland

New Holland in the Orkneys, Scotland

1. Introduction and Summary

2. Windflow™ 500 Track Record

3.

Proven 500 kW Wind Turbines, IEC Certified Design

4.

SyncWind

's Proprietary Technology

5.

Intellectual Property

1. Introduction and Summary

The Windflow™ 500 turbine combines synchronous generation with SyncWindi's

proven 2-bladed rotor with pitch-teeter coupling (PTC) and its advanced

teeter control system (TCS). This is ideal for turbulent, hill-top sites

where the light-weight, mid-size turbine facilitates road access and

craneage, and the 2-bladed rotor's PTC and TCS handle turbulence with

robustness and stability.

Past projects are testament to our commitment to

quality, and to the proven quality of our cost-effective certified wind

turbines that have extensive field experience in arduous conditions. These

include our wind farms in high wind sites in New Zealand (Gebbies Pass and

Te Rere Hau) and Scotland (Westray, New Holland and Ludenhill in the

Orkneys, Monan in the Outer Hebrides, Easter Aberchalder in the highlands

above Loch Ness, and Kingseat near Edinburgh). See our project gallery

for photos.

The Windflow™ 33-500 is

independently

certified

.

Windflow’s 500 kW turbine has been International Electrotechnical Commission

(IEC) certified by

Lloyd's

Register (class 1A to IEC 61400-1:2008, Edition 3) and has a

track-record of more than 1000 turbine-years of synchronous wind power

operation at over 95% availability. This means low risk to you and your

project, and more confidence in financing. .

Windflow’s 500 kW turbine has been International Electrotechnical Commission

(IEC) certified by

Lloyd's

Register (class 1A to IEC 61400-1:2008, Edition 3) and has a

track-record of more than 1000 turbine-years of synchronous wind power

operation at over 95% availability. This means low risk to you and your

project, and more confidence in financing.

With more than 1000 turbine-years operating experience and a fleet-wide

average availability of 95%+, the Windflow™ 500 has proven its robust

design and high reliability in some of the most challenging wind

conditions in the world.

|

|

|

2. Windflow™ 500 Track Record

|

|

See our

project gallery

for more photos. |

New Zealand, Te Rere Hau

Ninety-seven Windflow™ 33-500 turbines were installed

at the Te Rere Hau wind farm near Palmerston North, New Zealand between 2006

and 2011. This site exhibits some of the most challenging wind conditions in

the world, with greater than 10 m/s average annual wind speed. Some of the

turbines on site see monthly-average wind speed above 15 m/s. Many of the

turbines experience significant hill effects, and extreme turbulence and

wind shear. Despite these challenging conditions, the Windflow™ 33-500 has

proven itself by accumulating more than 1000 turbine-years of operation at

higher than 95% availability. |

|

See our project gallery

for more photos. |

United Kingdom

From 2013 to 2016, seven Windflow™ 33-500 turbines and

one Windflow™ 45-500 were installed in Scotland’s Highlands and Islands.

Despite the remote locations, all are grid-connected turbines feeding power

into the local utility grid. Most of the turbines see complex terrain

effects and high turbulence.

|

|

Independent Type Certification |

3. Proven 500 kW Wind Turbines,

IEC Certified Design

SyncWind. currently

offers two wind turbine products: the proven Windflow™ 33-500 for high wind

speed sites and the Windflow™ 45-500 for medium wind speed sites.

The Windflow™ 33-500 wind turbine has been

designed for a 20-year life at a Class 1A site in accordance with IEC

61400-1:2005 (Edition 3). It is a robust machine designed for sites with up

to 10 m/s average annual wind speed, and storms gusting up to approximately

70 m/s.

Independent Type Certification

was

awarded in September 2010 by

Lloyd's

Register. was

awarded in September 2010 by

Lloyd's

Register.

The Windflow™ 45-500 has been designed for a

20-year life at a Class 2A site in accordance with IEC 61400-1:2005. It is

designed for sites with up to 8.5 m/s average annual wind speed, and storms

gusting up to approximately 60 m/s. Prototype Windflow™ 45-500s have been

installed and site commissioned in Texas, USA in early 2015, and Scotland in

late 2016. |

|

|

Windflow™ 33-500 Turbine

|

Windflow™ 45-500 Turbine

|

|

|

|

|

|

4.

SyncWindi's

Proprietary Technology

SyncWindi

utilizes several cutting-edge technologies to enable

lightweight but high-performing and extremely robust wind turbine designs.

These include:

-

Two-bladed rotor, with SyncWindi's

proprietary Teeter Control System™, which combines passive load

shedding with improved stability and energy capture.

-

The patented

Torque Limiting Gearbox™,

which enables the use of a synchronous generator directly on line without

the need for expensive and unreliable power electronics.

-

SyncWindi's

proprietary Low Variable Speed

System™ reduces blade tip noise in low

wind conditions and improves energy capture.

On all wind turbines turbulence, wind shear, tower shadow, pitch imbalance

and yaw error cause an imbalance of loads on the rotor. Three-bladed

machines have no simple means of mitigating these loads, and without

sophisticated controls they are transmitted into the drivetrain and gearbox

causing substantial design and reliability problems.

Two-bladed rotors lend themselves to the use of a

teeter hinge, a well-tested and understood technology that passively

relieves most of the imbalanced loads on the rotor. Loads simulation

comparisons indicate a 50%+ reduction in main shaft bending fatigue loads

for teetering two-bladed machines versus comparably-sized three-bladed

machines. This translates into substantial reductions in weight and cost

throughout the turbine.

|

Teeter Control System™ |

a) Teeter Control System™

SyncWindi's

design extends this idea to incorporate pitch-teeter coupling, which

improves both energy capture and teeter stability during transients. These

features are embodied in SyncWindi's

proprietary Teeter Control System™.

The success of this design philosophy is evident in the

Windflow™ 500 products having the highest annual energy production (AEP,

measured in MWh/year) per tower top mass (measured in tonnes) in their

respective design classes. And since this is achieved through load

reductions rather than through exotic materials, it translates into an

extremely cost-effective design.

|

|

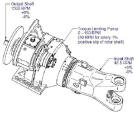

Torque Limiting Gearbox™

Diagram |

b)

Torque Limiting Gearbox™ (TLG)

Just as the Teeter Control System™ provides a passive means of mitigating

rotor imbalance loads, so does SyncWindi's

patented Torque Limiting Gearbox™ (TLG) provide a passive mechanical means

of removing torque transients from the drivetrain. The TLG provides

near-instantaneous response to torque transients, whether induced by the

wind or by electrical grid disturbances, thereby reducing torsional fatigue

and impact loads throughout the power-train. This results in a highly

reliable, low maintenance turbine.

The TLG has two output shafts. The majority of the wind

power captured by the rotor is transmitted through to the main output shaft,

which drives a synchronous generator, synchronized to the grid at 1500/1800

RPM.

The second output shaft drives a low-inertia torque

limiting pump. This pump energizes a proprietary hydraulic subsystem which

manages any rapid fluctuations in the input wind power by a combination of

storage and dissipation means.

The TLG protects the power-train from torsional impact

and fatigue and enables the use of a synchronous generator directly on line.

Synchronous generators eliminate the need for power electronic frequency

conversion, saving both upfront and maintenance costs. They also enable

abundant reactive power support for weak or unstable grids. This is a major

advantage in the markets seeking to maximise renewable energy capture.

|

|

|

c) Low Variable Speed System™

SyncWindi's

proprietary Low Variable Speed System™ enables the turbine rotor to run 40%

slower than its maximum RPM while maintaining the output shaft speed

constant. This improves aerodynamic efficiency and turbine output at lower

wind speeds, enables cut-in at lower wind speeds, and reduces blade tip

noise in low wind conditions.

|

|

|

5. Intellectual Property

The intellectual property SyncWindi

has available for manufacturing partners includes:

-

600+ turbine component drawings.

-

150+ drawings of special-purpose tooling.

-

50+ procedure drawings for nacelle assembly and

erection processes.

-

20+ detailed specification documents.

-

Detailed factory commissioning and field commissioning

procedures.

-

Operating manuals, maintenance manuals and various

repair procedures.

-

Bladed software models of the turbines for mechanical

loads analysis and performance simulations.

-

4000+ pages of detailed calculations to achieve IEC

Type Certification.

-

Comprehensive Type Testing reports for the Windflow™

33-500.

-

PLC turbine control software.

-

Turbine and wind farm SCADA software.

-

Extensive team know-how in 2-bladed wind turbine design

and control.

|

|

|

|

|